Military connectors

IFP - IFV - IFB Series

| For each industrial applications | ||||||||||||

|

|

IFP Series |

|

IFP series : Complying with MIL-C-26482

TECHNICAL FEATURES

Metallic parts Aluminium alloy complying with QQA-591, cadmium plating treatment complying with QQP-416 with green passivation- coupling pins in stainless steel Contacts Copper alloy with gold treatment on nickel Insertsi Synthetic rubber with high lagging - temperature 55°C : +125°C. |

Contacts

|

Electrical features |

|||

| Contact type | Work current | Test current | Tension Fall |

| 20 | 7.5 A | 7.5 | 25 mV |

| 16 | 22 A | 13 | 21 mV |

|

Mechanical features |

||||

| Contact type | Dope diameter | Hole depth | AWG max. | Max.section |

| 20 | 1.16 mm | 3.17 mm | 20 | 0.6 mm2 |

| 16 | 1.98 mm | 4.77 mm | 16 | 1.2 mm2 |

| Lagging on the sea level | ||

| Class | Work tension CA | Work tension CC |

| I | 500 | 700 |

| II | 900 | 1250 |

| Contacts distance | ||

| Class | Discharge run | Mechanical distance |

| I | 2.38 mm | 1.19 mm |

| II | 3.18 mm | 1.98 mm |

Click on images to enlarge

| Contacts disposal | Alternative disposals | |||||||||

| Disposal | Contacts | Contacts type | Dimension | Disposal | Degrees | |||||

| 20 | 16 | W | X | Y | Z | |||||

| 8-2 | 2 | 2 | 8 | 8-2 | 58 | 122 | ||||

| 8-3 | 3 | 3 | 8 | 8-3 | 60 | 210 | ||||

| 8-3A | 3 | 3 | 8 | 8-3A | 60 | |||||

| 8-4 | 4 | 4 | 8 | 8-4 | 45 | |||||

| 8-33 | 3 | 3 | 8 | 8-33 | 90 | |||||

| 10-6 | 6 | 6 | 10 | 10-6 | 90 | |||||

| 10-7 | 7 | 7 | 10 | 10-7 | 90 | |||||

| 10-98 | 6 | 6 | 10 | 10-98 | 90 | 180 | 240 | 270 | ||

| 12-3 | 3 | 3 | 12 | 12-3 | 180 | |||||

| 12-8 | 8 | 8 | 12 | 12-8 | 90 | 112 | 203 | 292 | ||

| 12-10 | 10 | 10 | 12 | 12-10 | 60 | 155 | 270 | 295 | ||

| 12-14 | 14 | 14 | 12 | 12-14 | 60 | 155 | 270 | 295 | ||

| 14-5 | 5 | 5 | 14 | 14-5 | 40 | 92 | 184 | 273 | ||

| 14-12 | 12 | 8 | 4 | 14 | 14-12 | 43 | 90 | |||

| 14-15 | 15 | 14 | 1 | 14 | 14-15 | 17 | 110 | 155 | 234 | |

| 14-18 | 18 | 18 | 14 | 14-18 | 15 | 90 | 180 | 270 | ||

| 14-19 | 19 | 19 | 14 | 14-19 | 30 | 165 | 315 | |||

| 14-91 HV | 3 | 3 | 14 | 14-91 HV | 60 | |||||

| 16-8 | 8 | 8 | 16 | 16-8 | 54 | 152 | 180 | 331 | ||

| 16-23 | 23 | 22 | 1 | 16 | 16-23 | 158 | 270 | |||

| 16-26 | 26 | 26 | 16 | 16-26 | 60 | 275 | 338 | |||

| 16-99 | 23 | 21 | 2 | 16 | 16-99 | 66 | 156 | 223 | 340 | |

| 18-11 | 11 | 11 | 18 | 18-11 | 62 | 119 | 241 | 340 | ||

| 18-30 | 30 | 29 | 1 | 18 | 18-30 | 180 | 193 | 285 | 350 | |

| 18-32 | 32 | 32 | 18 | 18-32 | 85 | 138 | 222 | 265 | ||

| 18-80 | 8 | 6 | 2-8 coax | 18 | 18-80 | 45 | 90 | 135 | 160 | |

| 20-16 | 16 | 16 | 20 | 20-16 | 238 | 318 | 333 | 347 | ||

| 20-24 | 24 | 24 | 20 | 20-24 | 70 | 145 | 215 | 290 | ||

| 20-25 | 25 | 25 | 20 | 20-25 | 72 | 144 | 216 | 288 | ||

| 20-27 | 27 | 27 | 20 | 20-27 | 72 | 144 | 216 | 288 | ||

| 20-39 | 39 | 37 | 2 | 20 | 20-39 | 63 | 144 | 252 | 333 | |

| 20-41 | 41 | 41 | 20 | 20-41 | 45 | 126 | 225 | |||

| 20-90 | 7 | 7 | 20 | 20-90 | 45 | 135 | 225 | 315 | ||

| 22-7 | 7 | 7-8 coax | 22 | 22-7 | 19 | 41 | ||||

| 22-21 | 21 | 21 | 22 | 22-21 | 16 | 135 | 175 | 349 | ||

| 22-32 | 32 | 32 | 22 | 22-32 | 72 | 145 | 215 | 288 | ||

| 22-34 | 34 | 34 | 22 | 22-34 | 62 | 142 | 218 | 298 | ||

| 22-36 | 36 | 36 | 22 | 22-36 | 72 | 144 | 216 | 288 | ||

| 22-41 | 41 | 27 | 14 | 22 | 22-41 | 39 | 135 | 264 | ||

| 22-55 | 55 | 55 | 22 | 22-55 | 30 | 142 | 226 | 314 | ||

| 24-61 | 61 | 61 | 24 | 24-61 | 90 | 180 | 270 | 324 | ||

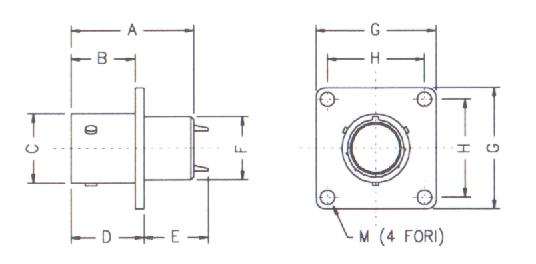

| Panel connectors - IFP02E | |||||||||||||

|

|||||||||||||

| Dimensions | A Max. | B +0.25 | C

+0.02 -0.12 |

D

+0.6 -0.25 |

E Max. | F Max. | G

±0.4 |

H

±0.4 |

M

±0.12 |

||||

| 8 | 21 | 10.95 | 12.01 | 16.5 | 11.8 | 11.4 | 20.6 | 15.1 | 3.04 | ||||

| 10 | 21 | 10.95 | 14.98 | 16.5 | 11.8 | 14.55 | 23.8 | 18.25 | 3.04 | ||||

| 12 | 21 | 10.95 | 19.05 | 16.5 | 11.8 | 17.75 | 26.2 | 20.6 | 3.04 | ||||

| 14 | 21 | 10.95 | 22.22 | 16.5 | 11.8 | 20.9 | 28.6 | 23 | 3.04 | ||||

| 16 | 21 | 10.95 | 25.4 | 16.5 | 11.8 | 24.1 | 31 | 24.6 | 3.04 | ||||

| 18 | 21 | 10.95 | 28.57 | 16.5 | 11.8 | 27.25 | 33.3 | 27 | 3.04 | ||||

| 20 | 27.4 | 14.1 | 31.75 | 16.5 | 13.4 | 30.45 | 36.5 | 29.35 | 3.04 | ||||

| 22 | 27.4 | 14.1 | 34.92 | 16.5 | 13.4 | 33.6 | 39.7 | 31.75 | 3.04 | ||||

| 24 | 28.2 | 15 | 38.1 | 17.3 | 12.5 | 36.8 | 42.9 | 34.9 | 3.73 | ||||

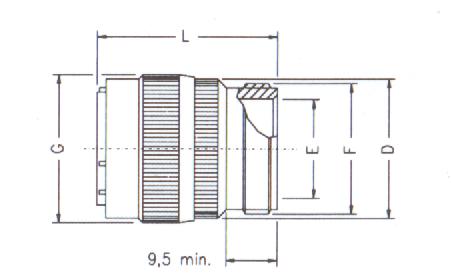

| Right steering wheel connector - IFP06A | |||||||||||||

|

|||||||||||||

| Dimensions | L Max. | E Min. | F Thread class 2A |

D Max. | G Max. | ||||||||

| 8 | 40.9 | 7.55 | .5000 - 28 UNEF | 15 | 19.05 | ||||||||

| 10 | 40.9 | 10.7 | .6250 - 24 UFEF | 18.2 | 21.8 | ||||||||

| 12 | 40.9 | 13.85 | .7500 - 20 UNEF | 21.2 | 26.2 | ||||||||

| 14 | 40.9 | 16.85 | .8750 - 20 UNEF | 24.6 | 29.4 | ||||||||

| 16 | 40.9 | 20 | 1.0000 - 20 UNEF | 27.6 | 32.55 | ||||||||

| 18 | 40.9 | 22.3 | 1.1875 - 18 UNEF | 30.9 | 35.35 | ||||||||

| 20 | 42.1 | 25.75 | 1.1875 - 18 UNEF | 33.8 | 38.9 | ||||||||

| 22 | 42.1 | 28.8 | 1.4375 - 18 UNFE | 37.1 | 42.1 | ||||||||

| 24 | 43.45 | 32 | 1.4375 - 18 UNFE | 40.25 | 45.1 | ||||||||

|

IFV and IFB Series |

|

IFV series: Complying with MIL-C-5015 IFB series: DFrom MIL-C-5015 Bayonet connection

TECHNICAL FEATURES

Metallic parts Aluminium alloy complying with QQA-591, cadmium plating treatment complying with QQP-416 Type II class C , with green passivation . They are different treatments . Contacts Copper alloy with silver gold treatment on nickel. You find contacts with gold treatment on silver or gold on nickel . Inserts Synthetic rubber with high lagging strong against oils and law temperatures (-55°C : +125°C) complying with MIL-R-3065.

|

Contacts

| Contact type | Max. current | Work current | Test current | Tension fall | Wire

section |

| 16 | 22 A | 13 A | 20 A | 21 mV | 16 - 18 - 20 - 22 AWG |

| 12 | 41 A | 23 A | 35 A | 20 mV | 12 - 14 AWG |

| 8 | 73 A | 46 A | 60 A | 12 mV | 8 - 10 AWG |

| 4 | 135 A | 80 A | 110 A | 10 mV | 4 - 6 AWG |

| 0 | 245 A | 150 A | 200 A | 10 mV | 0 - 1 - 2 AWG |

Lagging

| Class | Work

tension CC |

Work

tension CA |

Discharge

tens.VCA

min. |

Test

tension VCA |

| INST: | 250 V | 200 V | 1400 V | 1000 V |

| A | 700 V | 500 V | 2800 V | 2000 V |

| D | 1250 V | 900 V | 3600 V | 2800 V |

| E | 1750 V | 1250 V | 4500 V | 3500 V |

| B | 2450 V | 1750 V | 5700 V | 4500 V |

| C | 4200 V | 3000 V | 8500 V | 7000 V |

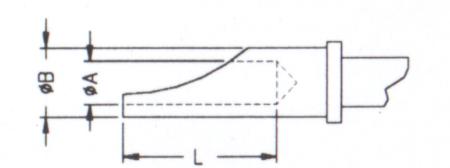

| Solding contacts dimension | |||

|

|||

| Contact type | A | B | L |

| 16 | 1.7 | 2.6 | 6.4 |

| 12 | 2.7 | 4.0 | 8.5 |

| 8 | 4.5 | 6.9 | 12.7 |

| 4 | 7.2 | 9.5 | 12.7 |

| 0 | 11.5 | 14.3 | 15.5 |

|

Remarks |

|

|

The constructor , in order to improve the product , will change dimensions without advance notice |

i.F-1 S.r.l. Via Cerallo 11 - 13100 - Vercelli - Italy - Tel. +39 0161 294314 - Fax +39 0161 294911 - P.IVA 01447940022